TABLE OF CONTENT

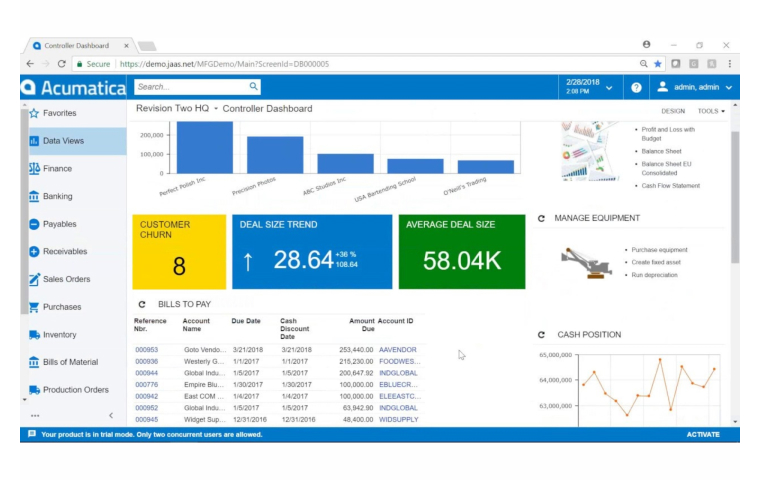

Key Features of Acumatica for Manufacturing

Overview of Acumatica's Integration Capabilities

Examples of Third-Party Applications that can be integrated with Acumatica for Manufacturing

Benefits of Acumatica for Manufacturing

Case Study

Conclusion

Key Features of Acumatica for Manufacturing

Various features are offered by Acumatica for manufacturing for the purpose of meeting businesses’ needs and these are several main features are listed below:

Bill of Materials (BOM)

With the help of Acumatica, businesses are able to access BOMs (all components) to justify what to produce or manufacture, inventory level tracking or product revision management. Holistic Management like that is beneficial for the factory as well as the head quarters.

Product Configurator

With the help of product configurator feature, you are able to customize new products, configure every product’s aspect such as color, material, size to perform the best product’s quotes.

Material Requirements Planning (MRP)

With the help of Acmatica’s MRP, manufacturers are able to perform inventory level and schedule production management better. Based on required forecasts and inventory levels, you are able to perform MRP process automatically and manufacturing plans more properly.

Production Management

With the help of production management, you are able to perform the production process from the beginning to the end better, as well as production orders, real-time progress or schedule resources.

Shop Floor Control

With the help of shop floor control, you are able to perform production activities monitoring and management better, as well as labor costs, schedule production and machine monitoring.

Quality Management

With the help of quality management, you are able to perform product quality tracking and management better, as well as plan control, non-conformances tracking or inspections.

Engineering Change Control

With the help of engineering change control, you are able to perform product changing management better, as well as change orders, approvals or the production schedules.

Advanced Planning and Scheduling (APS)

With the help of advance planning and scheduling (APS), you are able to perform production schedule optimization based on forecasts and resources, as well as APS process automation and production schedules. This would also prevent waste and extra costs.

Overview of Acumatica's Integration Capabilities

These are several integration selections which are offered by Acumatica:

- REST API: With the help of REST API, you are able to perform third-party integration better, as well as data exchange, data accuracy and manual process automation.

- Webhooks: With the help of webhooks, you are able to perform event notifications in real-time better, as well as order notifications or inventory levels reach.

- File-based Integration: With the help of file-based integration , you are able to perform data importation and exportation better, as well as batch process and system data automation.

Examples of Third-Party Applications that can be integrated with Acumatica for Manufacturing

Shop Floor Control Software

With the help of shop floor control software such as JobBOSS and ProShop, manufacturers are able to perform production schedules, resource utilization and inventory levels in real-time data better, as well as their operations, efficiency and less time-wasting.

E-Commerce Platforms

With the help of E-commerce platforms such as Shopify and Magento, manufacturers are able to perform order processing automation, shipping and inventory management better, as well as manual process, customer experience and data accuracy.

Quality Management Software

With the help of quality management software such as QT9 and CEBOS MO1, manufacturers are able to perform quality standards, corrective actions and non-conformances management better, as well as product quality, waste-reduced and risks.

Shipping and Logistics Software

With the help of shipping and logistics software such as ShipStation and ShipWorks, manufacturers are able to perform the shipping processes, returns and tracking automation better, as well as shipping errors management, customer satisfaction, and time/budget-saving.

Benefits of Acumatica for Manufacturing

Various advantages are provided by Acumatica to support manufacturers:

Increased efficiency and productivity

With the help of Aucumatica’s manufacturing, manufacturers are able to perform their manual processes and operations more effectively and productively. Manufacturers are also able to advance inventory levels and waste-reduced in real-time data.

Enhanced production planning and control

With the help of Acumatica for manufacturing, manufacturers are able to perform production schedules, real-time progress tracking and changes more efficiently.

Better cost management and financial reporting

With the help of Acumatica’s manufacturing, manufacturers are able to perform cost management and financial reports better, as well as cost analyzing and decision makings.

Increased visibility and data accuracy

With the help of Acumatica for manufacturing, manufacturers are able to perform organization data better, as well as make decisions and change conditions.

Case Study

There are four case studies which have discussed the successful manufacturing companies leveraging Acumatica and their implementation results and achievement in the end. Let’s go deeper!

Case Study 1: JW Machine

JW Machine is a rigor machine store which is located in Wichita, Kansas. This more than 20-year-old company highly focuses on high-precision CNC machining.

There are some difficulties such as real-time data lacking as well as manual processes and workflows that need JW Machine to tackle. Thus, Acumatic has become their choice for improving manufacturing for the purpose of advancing operations and productivity.

After then, the results had been credibly achieved by JW Machine with the help of Aucumatica’s manufacturing:

- Inventory accuracy increased by 50%

- Manual data entry decreased by 75%

- Order processing time increased by 40%

- Production schedules and labor costs’ visibility has been developed

Case Study 2: CyberMetrics Corporation

CyberMetrics Corporation is a software business which is located in Phoenix, Arizona. The company is highly focused on the quality management and calibration solutions development.

There are some difficulties such as system integration lacking, inventory levels visibility and manual processes that need CyberMetrics Corporation to tackle. Thus, Acumatic has become their choice for improving manufacturing.

After then, the results had been credibly achieved by CyberMetrics Corporation with the help of Aucumatica’s manufacturing:

- Reduced inventory levels by 20%

- Improved order processing time by 50%

- Increased visibility into inventory levels and production schedules

- Reduced manual processes and improved data accuracy

Case Study 3: VGS Seals

VGS Seals is a business which is located in Houston, Texas. The company is highly focused on the manufacture of high-performance seals and gaskets.

There are some difficulties such as inefficient workflows, manual processes or production schedules visibility that need VGS Seals to tackle. Thus, Acumatic has become their choice for improving manufacturing to advance operations and effectiveness.

After then, the results had been credibly achieved by VGS Seals with the help of Aucumatica’s manufacturing:

- Reduced order processing time by 30%

- Improved visibility into inventory levels and production schedules

- Increased efficiency and productivity

- Reduced manual processes and improved data accuracy

Case Study 4: Presidio Components

Presidio Components is a business located in San Diego, California. The company highly focuses on the manufacture of high-performance capacitors.

There are some difficulties, such as inadequate system integration, manual processes, or inefficient workflows, that need Presidio Components to tackle. Thus, Acumatica has become their choice for improving manufacturing to advance operations and effectiveness.

After then, the results had been credibly achieved by Presidio Components with the help of Aucumatica’s manufacturing:

- Reduced order processing time by 50%

- Improved inventory accuracy by 30%

- Increased visibility into production schedules and resource utilization

- Reduced manual processes and improved data accuracy

Read more:

Acumatica CRM Software: Streamline Your Customer Relationship Management Efforts

Acumatica Consulting: How to Find the Right Partner for Your Business

Conclusion

In conclusion, Acumatica for manufacturing is recommended for manufacturers as various advantages are provided such as operations streamline, productivity enhancement, cost-reducing and customer satisfaction development. As being in the expert team of Acumatica solutions, we could support manufacturers on their path of developing the implementation in order to advance the efficiency to the best.

Contact us today to get more information about Acumatica for manufacturing!