TABLE OF CONTENT

Advantages of Odoo for Manufacturing Industry

Odoo Modules for Manufacturing Industry

Case Study: Odoo in the Manufacturing Industry

Conclusion

Advantages of Odoo for Manufacturing Industry

Improved Supply Chain Management

Odoo’s supply chain executive module can assist manufacturers advance their supply chain by offering real-time data on inventory levels, purchase orders, and sales orders. This can support businesses make informed conclusions about procurement production and delivery.

Enhanced Production Planning and Scheduling

Odoo’s manufacturing module permits manufacturers to make strategy schedules, orders, and track processes in real-time. This can help businesses reduce lead times, control their management processes more effectively, and enhance shipping times.

Streamlined Inventory Management

With Odoo’s inventory module, companies can monitor their inventory achievements, brutalize reordering, and keep track of stock movements in real time. This can support businesses to avert stockouts, enhance order fulfillment rates, and diminish inventory holding costs.

Better Quality Control

Odoo’s value module can help enterprises carry out quality management measures, track quality issues, and evaluate root causes to address and identify quality problems. This can assist businesses to reduce waste, enhance product quality, and develop customer satisfaction.

Efficient Resource Utilization

By scheduling maintenance, tracking resource usage, and identifying production bottlenecks, Odoo’s production module can assist businesses control resources more effectively. This can support businesses to make perfect resource utilization, diminish downtime, and develop productivity.

Odoo Modules for Manufacturing Industry

Manufacturing Module

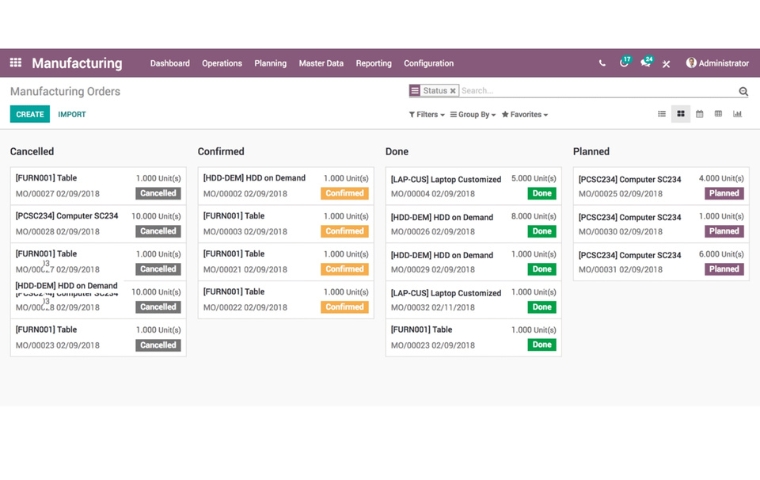

The manufacturing module is the main module for controlling work centers, production arrangements, and bills of materials. It permits manufacturers to strategies and manages production schedules, track process, and figure out costs.

Inventory Module

The inventory module assists companies control inventory levels, brutalizing reordering, and monitoring real-time stock movements. It lets companies track stock movements, perform inventory counts, and control several warehouses.

Quality Module

The value module permits companies to carry out quality management measures, track quality problems, and evaluate root reasons to identify and address quality issues. It assists companies to sustain consistent reduce defects, and quality standards, and developing customer satisfaction.

Purchase Module

The Odoo purchase module permits companies to control their procurement processes, track orders, and automate vendor payments. It supports businesses to discuss better prices, managing supplier relationships, and diminishing process costs.

Sales Module

The Odoo sale module allows businesses to manage their sales processes, track orders, and brutalize invoicing. It assists companies to control client relationships, follow sales accomplishments, and develop order fulfillment rates.

Case Study: Odoo in the Manufacturing Industry

Company Profile

The company is a medium-sized manufacturing business specializing in the production of buyer electronics. The enterprise has been in operation for over 20 years and has set up itself as a leader in the industry.

However, to streamline its processes and improve efficiency, the company faced demands in controlling its movements and sought a resolution.

Challenges

One of the biggest challenges the business faced was controlling its production progress. The company depended on a manual system for managing production orders, which made it hard to track progress, schedule resources effectively, and control inventory.

This brings about improved production costs, longer lead times, and poor on-time delivery rates.

The business also needed assistance with inventory administration. The manual system made it hard to keep track of inventory levels and led to stockouts and overstocking. This afforded lost sales, enhances holding costs, and poor client comfort.

Conclusively, the business’s supply chain administration could have been more effective. The manual system made tracking buy orders, controlling suppliers, and monitoring shipping times difficult.

This resulted in delayed shipments, enhanced procurement costs, and poor supplier relationships.

Solution

To address these challenges, the company carried out Odoo’s manufacturing, inventory, and purchase modules. The application was implemented by an Odoo implementation partner, who worked closely with the business’s administration team to modify the software to fit the company’s particular demands.

Manufacturing Module

The manufacturing module was carried out to bills of materials, control production orders, and work centers. It permitted the company to track progress, plan production schedules, and analyze costs.

This assisted the company advance its production progress, diminishing lead times, and enhancing on-time shipping rates.

Inventory Module

The inventory module was carried out to assist the business control its inventory levels, brutalizing reordering, and keeping track of real-time stock movements.

It permitted the enterprises to perform inventory counts, track stock movements, and control several warehouses. This assisted the business avoid stockouts, develop order fulfillment rates and diminish inventory holding costs.

Purchase Module

The purchase module was carried out to support the business control its procurement progresses, tracking buying orders, and automating vendor payments.

It lets the business control its supplier relationships, discuss better costs, and decrease procurement costs. This supported the business streamline its supply chain, develop supplier relationships and reduce costs.

Results

The implementation of Odoo for Manufacturing industry played an important role in influencing the business’s workings. The business achieved enhanced client comfort, recite business, and referrals with streamlined production processes, diminished lead times, and enhanced on-time shipping rates.

By supporting the business in averting stockouts, cut inventory holding costs, and improving order fulfillment rates, the inventory module was a vital part of this success. As a result, the business enjoyed developed sales, diminished prices, and enhanced client comfort.

Meanwhile, the purchase module assisted the enterprise in streamlining its supply chain, cutting costs, building better supplier relationships, developing procurement effectiveness, cost savings, and stronger supplier participation.

In general, the implementation of Odoo positively impacted the business’s workings and bottom line. The enterprise optimized its operations, diminished costs, and enhanced buyer satisfaction. The Odoo implementation partner implemented the performance quickly, and the business was able to modify the software to meet its unique requirements.

Conclusion

Odoo is an all-in-one business administration software that can assist manufacturers to enhance productivity, streamlining their workings, and diminishing costs. Its available production, inventory, value, sales modules, and procurement, can assist companies to control their production, and stock, and provide chain more effectively. Odoo is a great selection for small and medium-sized manufacturing companies finding to optimize their workings and improve with its user-friendly display, flexible customization selections, and economical pricing

In general, implementing Odoo can offer manufacturers a competitive edge by enhancing their supply chain administration, improving production strategies and scheduling, streamlining inventory administration, enabling better benefits management, and optimizing resource exercise. Companies can control their complete manufacturing progress from beginning to end and achieve real-time visibility into their operations with Odoo’s available modules. Businesses can gain better effectiveness, diminish costs, and enhance client satisfaction by carrying out Odoo

In conclusion, if you’re a manufacturing company finding out to streamline your workings, consider implementing Odoo as your all-in-one business administration aoolication. You can control your entire manufacturing progress from begin to finish and achieve real-time visibility into your operations with its numerous modules designed particular for manufacturing. Doing so can enhance your supply chain management, improve production strategy and scheduling, streamline inventory administration, enable better value control, and optimize resource utilization. Begin exploring Odoo now and take your manufacturing company to the next level!